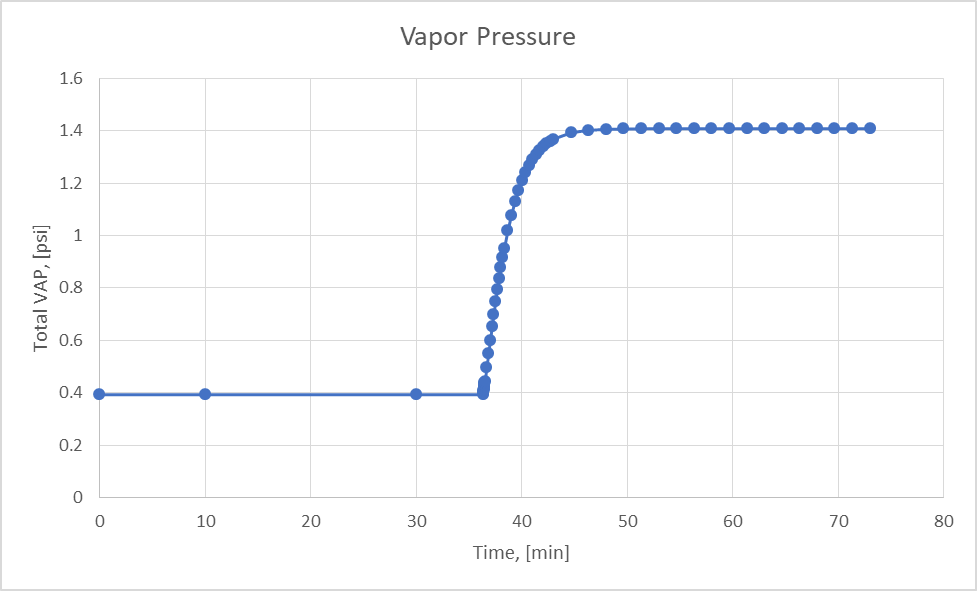

Problem formulation: A resource recovery division of a large cement plant burning waste fuels wanted to simulate the dynamics of a hydropulper to help understand the length of time it takes for the system to reach the 1.75 psi vent pressure. Items of particular interest were advised as follows:

- How quickly does the VP increase in a static condition using either the multitude of constituents in our static sheet, or the reduced number of constituents. Calculations must accommodate the following variables:

- Changes in volume of material in the unit

- Changes in the starting pressure within the tank

- Changes in the number constituents, using either the multitude of constituents in the provided static sheet, or a reduced number of constituents (e.g., methanol, benzene, and MEK).

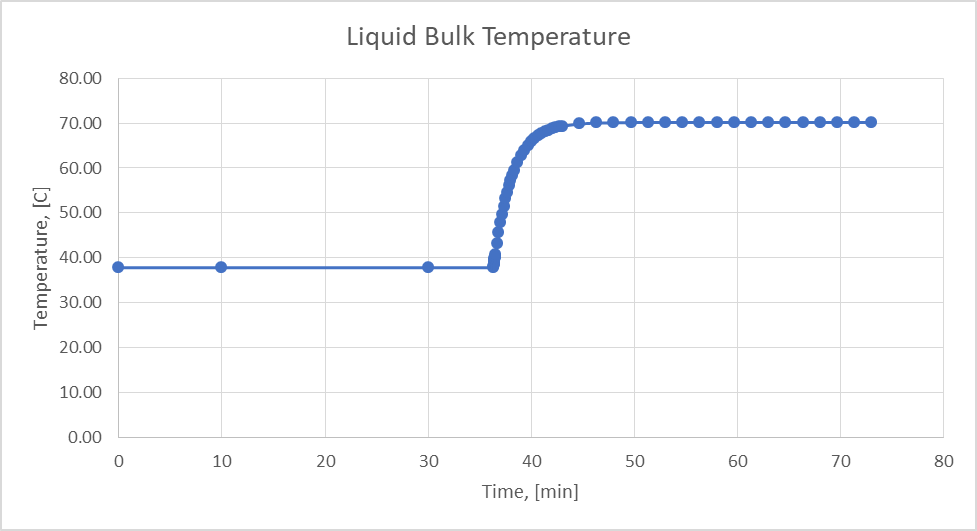

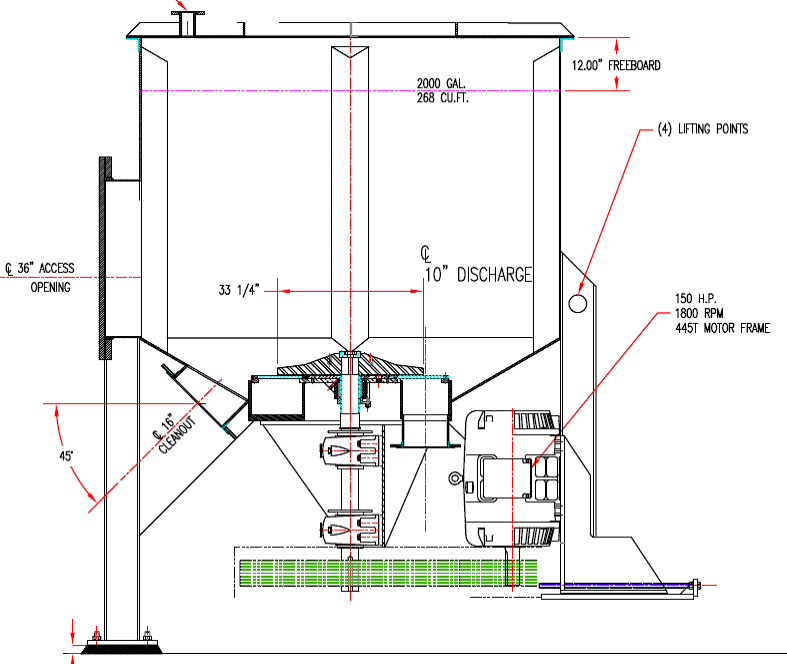

- What does the VP profile look like when the mixer is operating assuming the volume of material in the hydropulper remains constant, i.e., the volume of material entering the unit (dumping) is the same as the volume leaving the unit (pumped to the storage tanks), but it is being mixed/agitated.

Alpha-Thermal Solution:

With the thermodynamic properties of the bulk fuel constituents (150 compounds in all) a time-temperature and related time-vapor pressure response profiles were built considering input heat rate from ambient conditions and from the impeller (shown below). This was particularly important for US EPA compliance application purposes.